Spun-dyed Production

WHAT IS SPUN DYED / SPUN DYEING?

In order for the fabric in our clothing to have colour, there is a process of colour dyeing that takes place during production. The traditional method of piece dyeing fabrics means that rolls of fabric are dipped into large vats of water treated with the chemicals needed for dyeing. This method often results in excess water, chemicals and energy being consumed.

The method of spun dyeing uses:-

66% LESS WATER 75% LESS CHEMICALS 60% LESS CO2

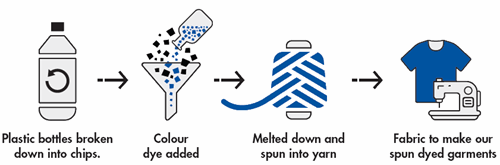

HOW DOES IT WORK?

We use recycled polyester that has been sourced from post-consumer waste, like plastic bottles and it is broken down in to smaller chips/pellets. Colour dye is then added directly to these polyester chips and they then go through a heating process where they are melted and extruded to form yarns. These yarns are then woven together to the make the fabric for our clothing.

PERFORMANCE BENEFITS

The process of adding colour dye directly into the polyester chips means there is a permanency and stability to the colour. The colour wont fade in UV light and can withstand washing up to 60C without suffering any long term colour degradation. Therefore, spun-dyed garments benefit from what is known as excellent colour fastness.